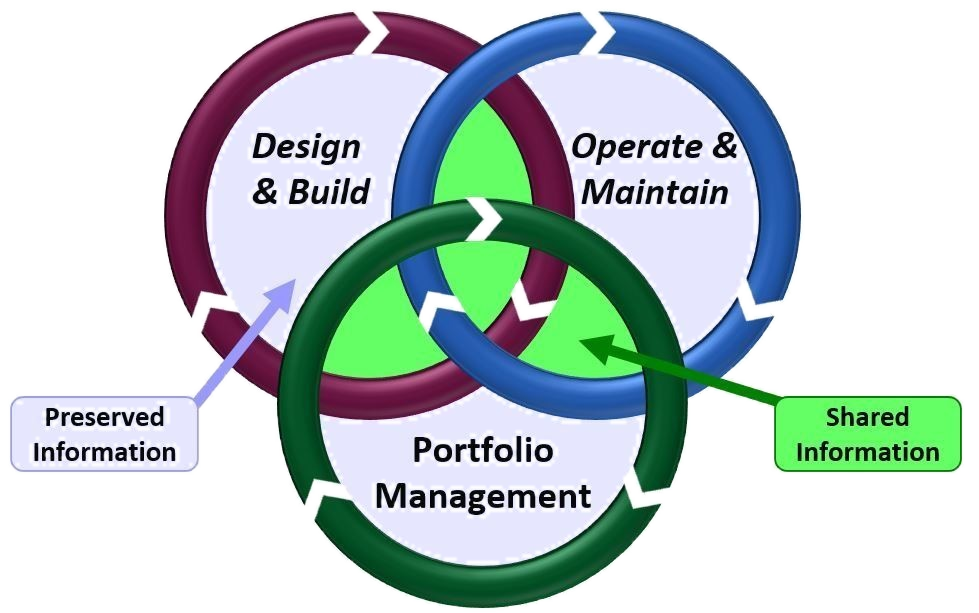

Asset lifecycle information management (ALIM) assures high data integrity across systems and the associated people during the lifecycle of an asset from design, commissioning, handover, operations and de-commissioning. A key function involves sharing of information so that all parties have the current document. It also involves governance for authorization to read, edit or replace with an audit trail.

ALIM Needed in Design & Build, and Operations

Good ALIM helps assure an upgrade project or new plant is built on time, in budget and on specification. Delays and rework are avoided when people have access to the current information when and where the need it. During operations, ALIM improves the data integrity of the various systems to avoid conflicts and support delivery of quality products on schedule.

Asset Lifecycle Information Management is Different

Asset lifecycle information management enables asset-intensive organizations to optimize the returns from their substantial investments in equipment and facilities. ALIM is needed by every asset-intensive organization to provide its people with good asset information. ALIM may appear to be similar to other information management challenges, like customer information management and product information management, but asset information has certain characteristics that merit special attention.